FrankenDeckel

Introduction

At my local scrapyard, a Deckel G1L engraver turned up one day. Actually there were two. Neither had a head, spindle or motor, since they the going price was only €20, I couldn't just abandon it could I?

Although designed for engraving, this is 250kg of quality german cast iron. The ways are broad and precise. Even with the goose neck, I am confident this is a more rigid stable machine base than a cheap chinese mill/drill with similar travels.

The table is 600x250mm and the travels are X=300mm, Y= 150mm and Z= 300mm. Should be quite well matched to the capacity of stuff which the FrankenSieg is capable of.

The only defects are that some idiot used the table to practise engraving, so it will need about 1mm milled off and then regrinding, and that the X leadscrew has a bent extension where the LH handle mounts . Not a show stopper, as the RH end is still fine to mount a handle.

FrankenDeckel is lurking in a friends shed until I get a spindle made up.

Update - OCT/2004

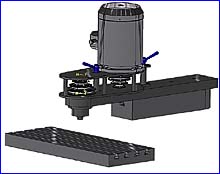

I had a guy machine the main head beam to accept the sherline spindle and am starting to make up the parts for this head.

I wrote to four different companies which do Laser cutting here in Austria to ask about getting the two head plates cut out of 6mm steel, but no one bothered to reply. I guess I just have to simplify them and do the slots on a mill at work, and the rest just a rough job.I guess I could just make them again properly once I have the rough one working.

The motor is a 1/2HP flange mount three phase 400V I got cheap on Ebay. Should be quite well matched to the little ER16 collet sherline spindle. Still need to get a VFD to drive it off single phase (no great hurry, the friends garage where the Deckel lives has three phase).

Update - 13/NOV/2004

The head is coming along well. Not the prettiest, but I can use the maill to make a nicer one once it is working. Just need to make the step pulleys and get a VFD.